The hull

- The shop-primed planks were cut out according to templates and precisely attached to a positive mold

- After tack-welding the planks, the hull was placed in a negative mold. Here, the plank seams were welded from the inside and the longitudinal ribs (the »stringers«) were inserted and tack-welded. There are two stringers per plank, and the bottom stringers are reinforced. This construction allows the boat to withstand consolidated pack ice

- After completion of the interior welding work, the shell was rotated again and the planks were welded from the outside and then trimmed.

This elaborate process created a particularly symmetrical and strutting hull. The keel and rudder-skeg structures were made separately and then welded to the hull.

Plate thickness is 4 mm (.16in) in the floor and window planks and 3 mm (.12in) in the sides. The plates in the area of the deck, the superstructure and the cockpit are 3 mm thick.

The deck and the cockpit »tub« are reinforced by beams or stringers.

All structures submitted to wear – such as anchor roller sides, the anchor box cover, hatch covers, bollards, handrails and chain plates – are made of stainless steel.

The diameter of the stainless steel rudder shaft is 40 mm (1.57in).

Bow and stern pulpits are made of particularly sturdy stainless steel tubing and are attached to the hull by stainless-steel bolts.

The hull is protected inside and out by a two-component coating system.

|

|

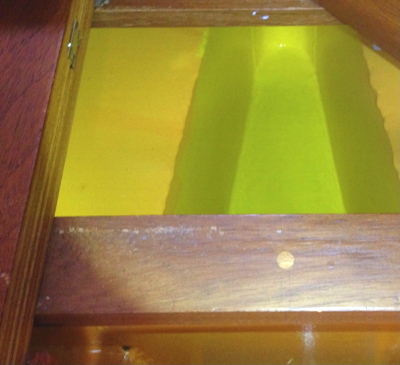

View of the bilge and the keel: Five coats of two-pot epoxy paint in the floor section, the bilge, the keel and under the engine make for a resilient and durable, smooth surface. The photo shows the current situation. |